English

| Name | Chemical formula | Main factors of scaling |

| Calcium carbonate | CaCO3 | Carbon dioxide partial pressure, temperature, salt content, pH value |

| Calcium sulfate | CaSO4·2H2O CaSO4 | Temperature, pressure, salt content |

| Barium sulfate Strontium sulfate | BaSO4 SrSO4 | temperature, salt content |

| Iron compounds ferrous sulfide iron hydroxide iron oxide | FeCO3 FeS Fe(OH)2 Fe(OH)3 Fe2O3 | Corrosion, dissolved gas, pH value |

Dangers of scaling

● Reduce heat transfer effect

● Cause corrosion of pipelines and equipment

● Reduce the cross-sectional area of water flow, increase water flow resistance and energy consumption

● Increased cleaning costs and production shutdown time

Existing methods and their drawbacks

| Existing methods | Fundamental | Disadvantages |

| Chemicals | Chemical energy | Pollution, corrosion, high cost |

| Electronic descaling | Polarization | Energy consumption and rapid decay of effect |

| Electrolyte | Electrolysis | Energy consumption and gas release require treatment |

| Ultrasound | Vibration | Energy consumption and rapid decay of effect |

| Ion rod | Polarization | Energy consumption and rapid decay of effect |

| Strong magnet | Magnetic field | Greatly affected by temperature |

Detailed explanation of anti-scaling principle

| The overall electric current of the alloy is -0.360V | |

| Cu +0.35 | Sn -0.14 |

| Ni +0.25 | Zn -0.76 |

| Ag +0.79 | Fe-0.40 |

Increase solubility

Under the electrochemical action of the metastable functional alloy, the fluid characteristics change, breaking the large water molecule clusters originally associated with H bonds, causing polarization deformation of the water molecule clusters associated with H bonds, and improving the strength of the original minerals. solubility.

Free electrons

The 'free electrons' released by the alloy can be captured by ions with low electronegativity such as Ca2+, Mg2+, Fe2O3, etc.This causes Ca2+ and Mg2+ to break away from CO32-, SO42- and HCO3- to form atomic structures (Ca0, Mg0).When they are in aqueous solution, their ionic bonds are broken; or when they are in the state of precipitated solids, that is, scale, their lattice bonds are broken, which fundamentally changes the tendency of scale crystal nucleation or makes it difficult to form large-scale crystals. nuclear.

Free electrons

The 'free electrons' released by the alloy can be captured by ions with low electronegativity such as Ca2+, Mg2+, Fe2O3, etc.This causes Ca2+ and Mg2+ to break away from CO32-, SO42- and HCO3- to form atomic structures (Ca0, Mg0).When they are in aqueous solution, their ionic bonds are broken; or when they are in the state of precipitated solids, that is, scale, their lattice bonds are broken, which fundamentally changes the tendency of scale crystallization and nucleation or makes it difficult to form large-scale crystals. nuclear.

Free electrons

The 'free electrons' released by the alloy can be captured by ions with low electronegativity such as Ca2+, Mg2+, Fe2O3, etc.This causes Ca2+ and Mg2+ to break away from CO32-, SO42- and HCO3- to form atomic structures (Ca0, Mg0).When they are in aqueous solution, their ionic bonds are broken; or when they are in the state of precipitated solids, that is, scale, their lattice bonds are broken, which fundamentally changes the tendency of scale crystallization and nucleation or makes it difficult to form large-scale crystals. nuclear.

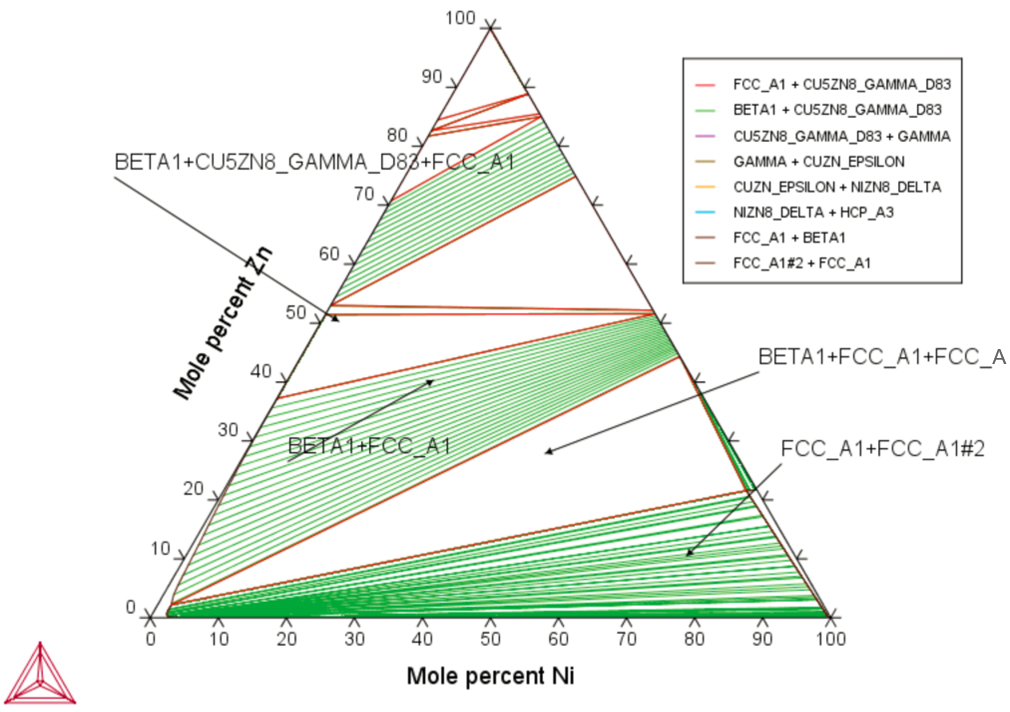

CuNiZnM (M:Pb, Sn, Fe, Co, Sb, RE)

| Half reaction | Standard electrode potential (V) | Half reaction | Standard electrode potential (V) |

| Cu | - | Fe | - |

| Cu²++2e-⇌Cu | 0.340 | Fe³++e-⇌ Fe²+ | 0.771 |

| Cu²++e-⇌Cu+ | 0.159 | Fe²++2e-⇌ Fe | -0.44 |

| Cu++e-⇌Cu | 0.520 | sb | - |

| Ni | - | Sb+3H2O+3e-⇌SbH³+3OH- | -1.338 |

| Ni²++2e-⇌Ni | -0.257 | Sb+3H++3e-⇌SbH³ | -0.510 |

| Zn | - | Co | - |

| Zn²++2e-⇌Zn | -0.7626 | Co²++2e-⇌ Co | -0.277 |

| Pb | - | RE | - |

| Pb²++2e-⇌Pb | -0.126 | Ce³++3e-⇌Ce | -2.34 |

| Pb4++2e-⇌Pb²+ | 1.65 | La³++3e-⇌La | -2.38 |

| Sn | - | Er³++3e-⇌Er | -2.32 |

| Sn²++2e-⇌Sn | -0.1375 | Y³++3e-⇌Y | -2.37 |

| Sn4++2e-⇌Sn²+ | 0.154 |